ABB robotic motors

ABB robotic motors are known for their high performance, reliability, and precision. They are typically used to drive the various axes and joints of industrial robots, providing the necessary power and control for precise movements and positioning.

ABB offers different types of robotic motors, including servo motors and stepper motors, to cater to different application requirements. Servo motors are commonly used in applications that require high-speed and high-precision motion control, while stepper motors are often used in applications that require precise positioning and torque control.

Motor Type:

1. Servo Motors: ABB offers servo motors for precise motion control, high-speed applications, and dynamic performance. These motors provide accurate position and velocity control, making them suitable for applications that require precise movements and responsiveness.

2. Stepper Motors: ABB also provides stepper motors that offer precise positioning and control in applications that require accurate step increments and holding torque. Stepper motors are commonly used in applications that prioritize position control over high-speed operation.

Motor Size:

ABB robot motors come in various sizes to cater to different robot models and payload capacities. Motors may be classified based on their physical dimensions, such as frame size or flange size, to ensure compatibility with specific robot configurations.

Performance Characteristics:

1. Power Rating: ABB robot motors can be classified based on their power rating, typically measured in kilowatts (kW) or horsepower (HP). Higher power motors are capable of driving larger robots or handling heavier payloads.

2. Speed and Torque: Motors can also be classified based on their speed range and torque output. ABB offers motors with different speed and torque characteristics to meet varying application requirements, ranging from high-speed, low-torque motors to low-speed, high-torque motors.

Application Suitability:

ABB robot motors may be classified based on their suitability for specific applications or industries. For example:

1. General Purpose Motors: These motors are versatile and suitable for a wide range of industrial applications, including assembly, material handling, and machine tending.

2. High-Speed Motors: ABB offers motors optimized for high-speed applications, such as pick and place operations, packaging, or fast assembly tasks.

3. Heavy-Duty Motors: Some motors are designed for heavy-duty applications that involve handling large payloads or require high torque output, such as welding, material removal, or heavy part manipulation.

The principle of ABB motor

The working principle of ABB motors is based on the theory of electromagnetic induction. The motor consists of a stator and a rotor. The stator is wound with a three-phase winding, which provides a three-phase current through an AC power supply to form a rotating magnetic field. There is a conductor around the rotor, and when the rotor moves in the rotating magnetic field, the conductor is affected by the electromagnetic force, which turns the motor shaft.

The working principle of ABB motors can be explained by Fleming's rule and Lenz's law. Fleming's law states that when a conductor moves in a magnetic field, it will experience a certain amount of electromagnetic force. Lenz's law states that when a conductor moves in a magnetic field, an induced electromotive force is generated in the conductor, resulting in an electric current.

The use of ABB's robotic motors

1. ABB robot motors are designed to seamlessly integrate with ABB robotic systems. They are engineered to work in harmony with the robot's control system, ensuring precise and reliable performance.

1. ABB robot motors are known for their high performance characteristics. They are designed to deliver optimal torque, speed, and efficiency, enabling robots to carry out complex tasks with accuracy and repeatability.

3. ABB provides customization options for their robot motors to meet specific application requirements. This includes options for motor size, power rating, and other parameters, allowing users to select the most suitable motor for their needs.

4. ABB robot motors incorporate various safety features to ensure the well-being of operators and surrounding equipment. These features may include built-in sensors for monitoring temperature, vibration, and current, as well as protection mechanisms to prevent motor overheating or damage.

5. ABB emphasizes energy efficiency in their motor designs. Their motors are engineered to minimize energy consumption, contributing to cost savings and environmental sustainability.

6. ABB provides comprehensive support and maintenance services for their robot motors. This includes technical assistance, spare parts availability, and preventive maintenance programs to maximize the lifespan and performance of the motors.

Q:What is the role of ABB robotic motors

A:Motors are integral components in ABB robots, enabling precise motion control, payload handling, speed and acceleration control, and providing essential feedback for monitoring and safety purposes. Their performance and reliability are critical for the overall functionality and productivity of ABB robotic systems.

Q: How to package ABB robotic motors when it is delivered

A: First, select packaging materials that provide adequate protection against shock, vibration and potential operating hazards. The motor is properly secured in the package to prevent movement or displacement during transportation. Use appropriate fastening mechanisms, such as straps, foam inserts, or brackets, to keep the motor firmly in place.

Second, use strong packing tape or strapping tape to reinforce the package and prevent it from falling off. And take additional waterproof measures.

Finally, the necessary information, such as motor model, serial number, destination address and handling instructions, is clearly marked on the package.

Model of ABB robot motor

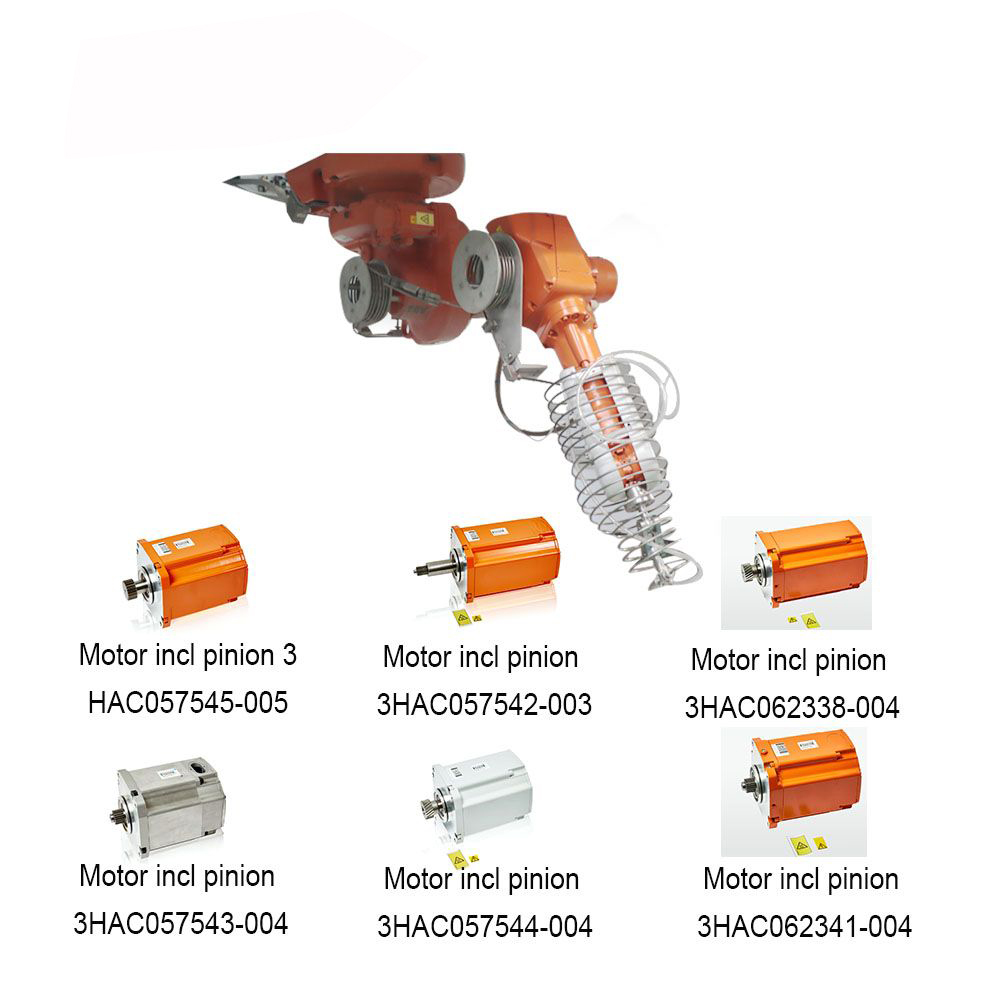

PICTURE

DETAILS

Product Net Weight/kg

Gross Weight/kg

Product Net Depth / Length/mm

Product Net Height/mm

Product Net Width/mm

3HAC057543-004

Motor incl pinion

23.2

23.2

270

180

180

HAC057544-004

Motor incl pinion

11.1

11.1

235

165

130

HAC057545-005

Motor incl pinion3

26

26

3HAC057542-003

Motor incl pinion

3HAC062338-004

Motor incl pinion

3HAC062341-004

Motor incl pinion

22.8

22.8

NUMBER

290

185

185

33

33

410

180

180

8

8

280

180

180

280

180

190

Project

This is a picture of an ABB robot project that winiwnrobot has done. winiwnrobot specializes in providing tailor-made robot water jet cutting solutions for automotive interior, exterior, aerospace, shipbuilding and other industries. Since 2013, we have provided solutions for more than 500 large enterprises, and our customers include Perger, Autor, Antonglin and other world-renowned enterprises, and have reached long-term cooperative relations.Win-Win currently has partners in many places around the world, such as America, Europe, Southeast Asia, West Asia, etc., we can provide users with fast and effective service, whether it is intended customers, new customers, old customers we can provide you with free technical consulting services.

CATEGORIES

LATEST NEWS

-

Christmas and New Year greeting

As the year draws to a close and the holiday sea

-

ABB robotic motors

ABB's robotic motors are known for their high pe

-

ABB Robot Company introduction

ABB is a leading global provider of industrial r

CONTACT US

Contact: WIN WIN ROBOT

Phone: +86 159 4239 2116

Tel: +86 159 4239 2116

Email: sales@wwrobotic.com

Add: Pacific industry zone, Shenyang, Liaoning province, China