6650s industry robot details

The ABB IRB 6650S is a versatile and high-performance industrial robot renowned for its speed, precision, and reliability. Designed to meet the demands of modern manufacturing environments, the ABB IRB 6650S offers advanced features that make it an ideal choice for a wide range of industrial applications.

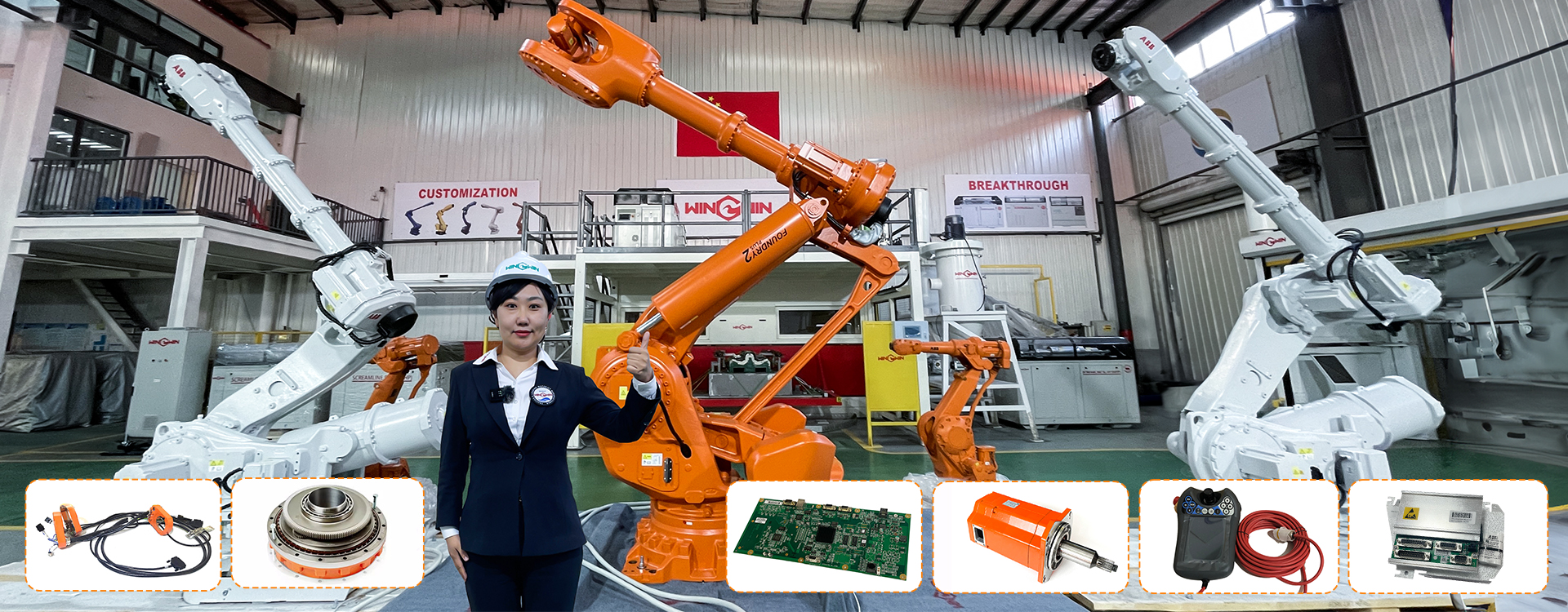

Overview of the ABB IRB 6650S Industrial robot

The ABB IRB 6650S is a member of ABB's popular IRB 6650 robot series, known for its strength, speed, and flexibility. This robot model is characterized by its high payload capacity, long reach, and exceptional repeatability, making it suitable for various tasks in industries such as automotive, metalworking, and general manufacturing.

Key Features of the ABB IRB 6650S

High Payload Capacity: The IRB 6650S is capable of handling heavy payloads, making it well-suited for applications that involve lifting and manipulating large objects with precision.

Long Reach: With a maximum reach of up to 3.5 meters (11.5 feet), the robot can access a wide range of workspaces and perform tasks that require extended reach.

Fast and Precise: Equipped with advanced motion control technology, the IRB 6650S delivers high-speed performance while maintaining accuracy and repeatability, ensuring efficient and reliable operation.

Flexible Configuration: The robot can be configured with various end-effectors and tools to accommodate different tasks and applications, providing flexibility and versatility in industrial settings.

User-Friendly Programming: ABB's intuitive programming software allows users to easily program and control the IRB 6650S, reducing setup time and enabling quick deployment in production environments.

Applications of the ABB IRB 6650S Robot

The ABB IRB 6650S robot is well-suited for a variety of industrial applications that require precision, speed, and reliability. Some common applications of the IRB 6650S include:

Welding: The robot is often used for arc welding, spot welding, and other welding processes that demand high precision and repeatability.

Material Handling: The IRB 6650S excels in tasks that involve palletizing, packing, and transferring heavy materials in manufacturing and logistics operations.

Machine Tending: The robot can be deployed for loading and unloading tasks in CNC machines, presses, and other automated equipment, enhancing productivity and efficiency.

Assembly: The IRB 6650S is capable of performing assembly tasks that require precise positioning and handling of components in assembly lines.

Conclusion

The ABB IRB 6650S industrial robot is a versatile and reliable solution for a wide range of manufacturing applications. With its high payload capacity, long reach, speed, and precision, the IRB 6650S offers the performance and flexibility needed to optimize production processes and enhance operational efficiency in industrial environments. Whether in welding, material handling, machine tending, or assembly, the ABB IRB 6650S is a valuable asset for businesses looking to streamline their operations and achieve greater productivity.

CATEGORIES

LATEST NEWS

-

Unveiling WWROBOT: Your Ultimate D

In the realm of industrial automation, precision

-

The Evolution of ABB Robotics: A J

In the realm of industrial automation, ABB Robot

-

what you know about ABB robot ?

The ABB 2600 robot is a versatile and high-perfo

CONTACT US

Contact: Win Win

Phone: +86 159 4239 2116

Tel: +86 159 4239 2116

Email: sales@wwrobotic.com

Add: Pacific industry zone, Shenyang, Liaoning province, China